Page Program Time for Winbond Serial NOR Flash Memory

Introduction

This application note explains how programming time may be reduced with Winbond Serial NOR Flash in the production line under certain conditions.

Skip the Chip Erase

Winbond SpiFlash has confirmed that all the parts are in the blank state before the shipment, therefore the user doesn’t need to erase the chip prior to programming. If the user wants to confirm the erase state, it is recommended to use the blank check command

The Page Program Time (tPP)

· tPP typical : Most of pages take typical tPP of the spec under the nominal conditions like 1.8V/3V (by Vcc range) and room temperature.

· tPP maximum : tPP maximum values are reflected by endurance because cell degradation may happens with P/E cycling.

The Efficiency of Data Input

· tPP only represents the page programming time. It doesn’t include time to input the instruction, address and data thus, faster clock frequency will reduce the overall programming time due to faster input.

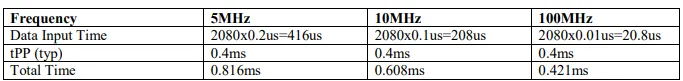

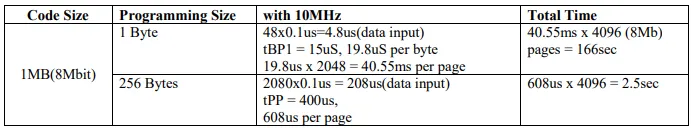

· Full 1 page program time calculation by frequency.

Note:

1. tPP is based on the typical spec in W25QXXEW Datasheet.

2. 2080 = 2048 bits per page + 8 of instruction + 24 of address.

· It is strongly recommended to perform full page programming. Otherwise, the offset time like internal regulation time will increase the programming time.

Note:

1. The programming time calculation is not including the offset time by RD/BY polling latency, so the polling latency has to be minimized.

Conclusion

It is recommended to skip the chip erase if the device is fresh from the factory and use the fastest frequency possible while ensuring signal integrity. Full page programming is strongly recommended to minimize the overhead.

Revision History

Trademarks

Winbond, SpiFlash and SpiStack are trademarks of Winbond Electronics Corporation.

All other marks are the property of their respective owner.

Important Notice

Winbond products are not designed, intended, authorized or warranted for use as components in systems or equipment intended for surgical implantation, atomic energy control instruments, airplane or spaceship instruments, transportation instruments, traffic signal instruments, combustion control instruments, or for other applications intended to support or sustain life. Furthermore, Winbond products are not intended for applications wherein failure of Winbond products could result or lead to a situation wherein personal injury, death or severe property or environmental damage could occur. Winbond customers using or selling these products for use in such applications do so at their own risk and agree to fully indemnify Winbond for any damages resulting from such improper use or sales.

Information in this document is provided solely in connection with Winbond products. Winbond reserves the right to make changes, corrections, modifications or improvements to this document and the products and services described herein at any time, without notice.

AN0000019

Publication Date: March 30, 2018 Revision 1.0