Brushless DC Motor IC (BLDC)

BLDC motors have become the cornerstone of various high-performance applications, demanding not just efficiency but also precision and low noise. Unlike their counterparts – induction motors, servo motors, and brushed DC motors – BLDC motors offer unparalleled efficiency and speed, coupled with substantial torque.

However, this heightened performance necessitates sophisticated electronic drivers to harness their full potential as they have electrical windings which needs to be energised to get the motor moving and the current in the windings needs to change continuously to provide consistent torque and speed.

A distinctive advantage of BLDC motors lies in their absence of mechanical commutators and brushes, thus there are no wear and tear concerns. This key design feature significantly enhances the service life of BLDC motors, ensuring consistent, reliable, and enduring performance.

In the realm of semiconductor technology, Nuvoton stands as one of the leading players, specialising in the development of integrated circuits tailored for industrial, automotive, communication, consumer, and computer markets. A key focus of our innovation lies in the realm of Brushless DC (BLDC) motor drivers, where Nuvoton's solutions are known for their advantages in efficiency, control, and reliability.

Nuvoton's BLDC motor drivers, equipped with our proprietary Auto Phase Control (APC) technology, redefine motor control paradigms. APC streamlines the adjustment of motor current phases, a task traditionally requiring meticulous fine-tuning. Moreover, the Advanced Phase and Rapid Soft Switching (APRaS) technology utilised by KA44171A optimizes high-speed motor operations while drastically reducing noise levels. With Nuvoton motor driver ICs, businesses can seamlessly integrate BLDC motors into their 12V and 24V systems, the most prevalent voltage standards in the market. All the Nuvoton's BLDC motor drivers support industrial operating temperature as -40~105 °C.

Our solutions offer a guarantee not just of consistent operations but also of enhanced performance and reliability, reaffirming Nuvoton's commitment to elevating the standards of efficiency and dependability in motor control technology. The motor driver ICs present here can be used for applications like data servers, base stations, home appliances, office automation and factory automation.

The availability of many control methods like PWM, DC control and both PWM and DC in the case of KA44143A and KA44171A gives you the flexibility to design the system according to your requirements and ensure the appliance works as intended. With small-sized IC packages like QFN and TSSOP, these driver ICs can be used in applications where space is at a premium. These are very popular package types so you would not need special BGA machines in manufacturing and designing the tester equipment for the EOL testing or fault testing will not be an issue for the line operators in factory. The low R(on) means high efficiency during operation and KA44169AB and KA44171A have sleep mode which can further reduce the amount of current flowing through the IC to take the efficiency to a notch higher.

Unique Technology:

APC (Auto Phase Control)

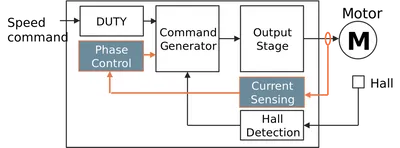

Compared to traditional motor drivers, Nuvoton incorporates features such as Phase control and Current sensing, matching the motor current phase with BEMF phase. The addition of current sensing at the output allows feedback to the phase control for comparison, enabling automatic corrections of phase errors. This achieves auto phase control.

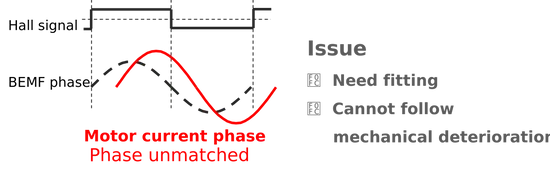

Without APC (Auto Phase Control), phase mismatch occurs at high rotation speed. Although initially fitting for phase is effective to avoid this mismatch, impossible to adapt to mechanical deterioration over time, resulting in low efficiency and short longevity.

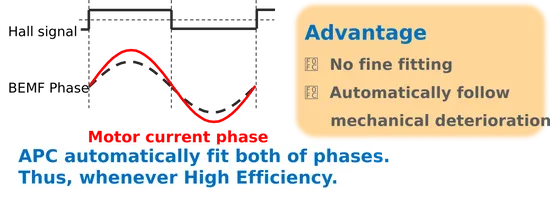

With APC (Auto Phase Control) technology, it can automatically correct the matching of the motor current phase with BEMF phase, leading to higher efficiency. The advantages include no fine fitting and automatic adaptation to mechanical deterioration.

APRaS (Advanced Phase & Rapid Softswitch)

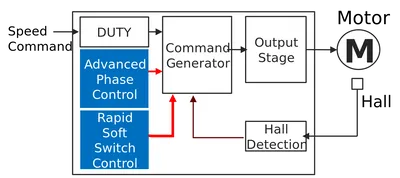

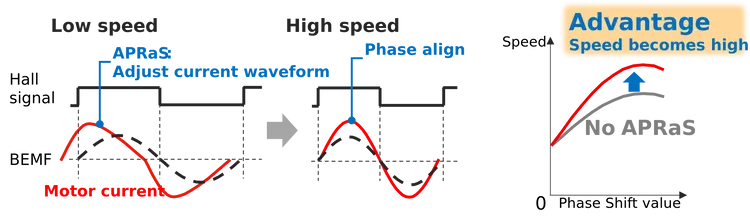

Compared to traditional motor drivers, Nuvoton incorporates Advanced Phase Control and Rapid Soft-switch Control algorithms to control the motor current phase and shape. Particularly, in applications with high-speed requirements, Nuvoton's unique technology, APRaS (Advanced Phase and Rapid Soft-switch), effectively increases the maximum motor speed.

Without APRaS(Advanced Phase & Rapid Softswitch), advanced phase adjustment itself may be possible even in conventional motor driver. However, the motor current shape cannot be set. So, when the motor operates at high speeds, an issue arises with current peak delay. This results in an inability to further increase motor speed, thereby hindering optimal motor performance.

With APRaS(Advanced Phase & Rapid Softswitch), the phase of the motor current can be advanced compared to BEMF through advanced phase technique, and the rapid-rise and slow-fall shape of the motor current can be set through rapid softswitch technique. As the motor begins to increase in speed, the phase can align with BEMF. Through this operation and control, it is possible to allow the motor speed to further increase, thereby improving overall motor performance.

Applications:

Server fan, Cellular Base station cooling, Factory automation, Refrigerator, Projector, Printer and Home appliance like clean robot.

Evaluation Board:

The evaluation board and its user manual serve as development auxiliary components, facilitating the assessment of motor driver functionality and features when connected to a motor. By effortlessly evaluating the motor driver using this auxiliary component, product development can be promptly initiated, thereby reducing time to market. Nuvoton provides corresponding development boards for each motor driver IC, enabling users to conduct testing.