Winbond > Part Catalog/ Mobile DRAM > HYPERRAM™

HYPERRAM™

Winbond Electronics introduced its first HYPERRAM™ products with densities ranging from 32Mb to 128Mb in 2015, shortly after the introduction of the HyperBus technology in the prior year. In 2021, Winbond further extended its HYPERRAM™ product offerings using its 25nm process technology, achieving densities of up to 256Mb and 512Mb.

These are HYPERRAM™ products available for purchase on TECHDesign platform

* Should you have any questions or would like to connect with technical team, please submit RFQ or contact us directly.

What is HYPERRAM™ ?

HYPERRAM™ is a cutting-edge solution that supports the HyperBus interface. The first-generation HYPERRAM™ offers a remarkable throughput of up to 333 MB/s, while HYPERRAM™ 2.0 pushes the boundaries further, reaching up to 400 MB/s.

HyperBus is a low-signal-count, Double Data Rate (DDR) interface known for its high-speed read and write capabilities. This technology, initially introduced by Cypress in 2014, combines the strengths of both parallel and serial interface memories, enhancing system performance, design simplicity, and cost-efficiency.

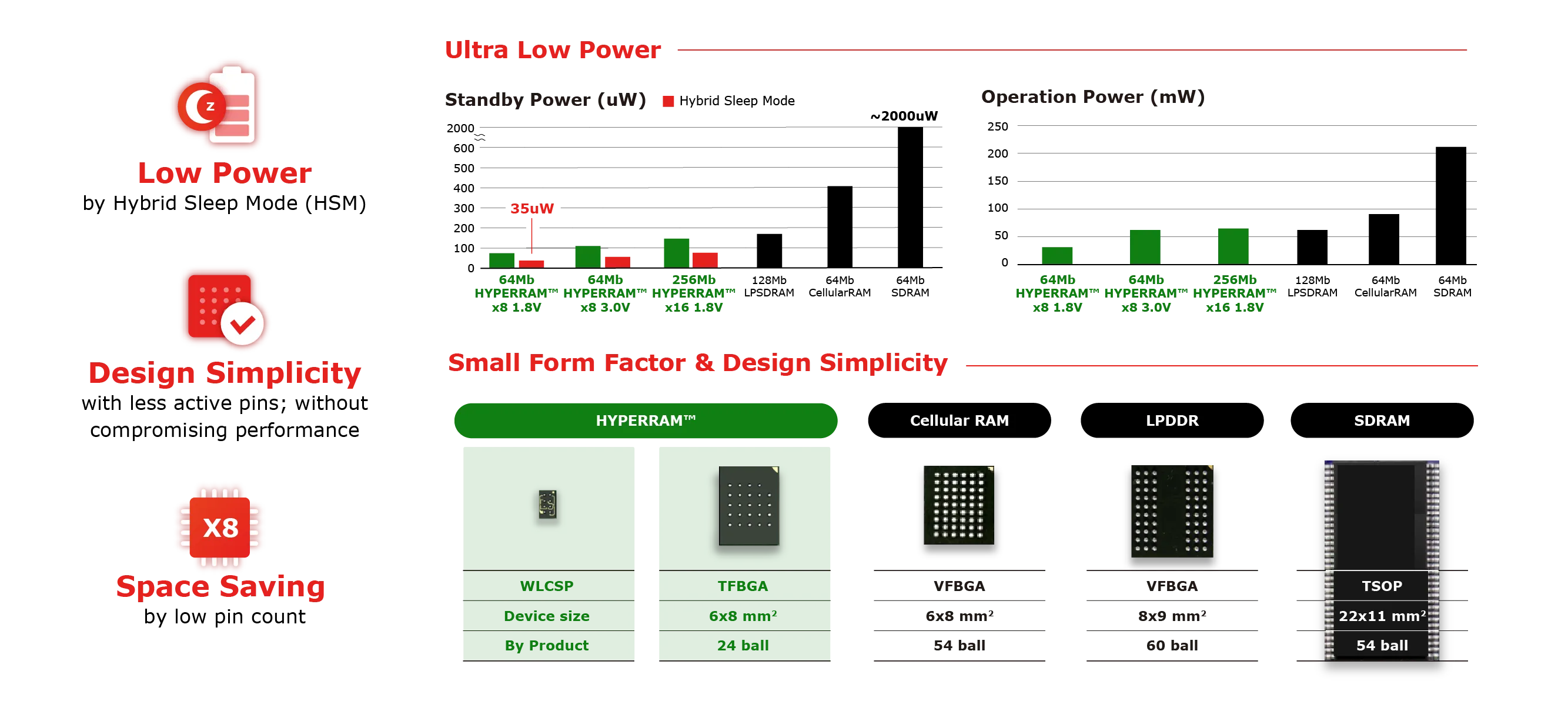

Winbond's HYPERRAM™ stands out for its design simplicity, space-saving attributes, and low power consumption, all while delivering exceptional performance. Its reduced signal count minimizes routing area, and it is available in small form factor packages, further reducing design footprint.

HYPERRAM™ memory is particularly suited for applications that demand both low power consumption and robust MCU computing power. Examples include automotive dashboards, HMI industrial control panels in the industrial 4.0 sector, voice control devices in smart homes, and smart bands in the wearables market. Moreover, HYPERRAM™ boasts ease of control with its low pin count (only 13 signal pins) and comparable bandwidth to other DRAMs or pSRAMs. The self-refresh feature simplifies system memory usage and streamlines firmware and driver development.

What are the benefits of HYPERRAM™ ?

HYPERRAM™ offers several key advantages:

Low Power Consumption: Through Hybrid Sleep Mode (HSM), Winbond's HYPERRAM™ achieves standby power consumption as low as 35μW, operating on less than half the power of equivalent pSRAM products. For instance, Winbond's 64Mb HYPERRAM™ consumes only 90uW at 1.8V and 110uW at 3V in standby mode, compared to approximately 2000uW at 3.3V for the same capacity SDRAM. The power consumption of HYPERRAM™ in Hybrid Sleep Mode is just 45uW at 1.8V and 55uW at 3V, significantly lower than the SDRAM standby mode.

Fewer Signal Pins: With only 13 signal pins, HYPERRAM™ simplifies PCB layout design and offers more PIN-outs for other use cases compared to designs with traditional DRAMs. This reduced pin count also enhances cost-effectiveness and simplifies control interface, automatically returning to Standby mode after read/write operations.

Smaller Form Factor: Winbond supports small form factor solutions to save space. Low pin-count packages and fewer host controller connections reduce the system board's footprint, making HYPERRAM™ ideal for compact devices like wearables.

Power Efficiency in Mobile and IoT Applications: HYPERRAM™ outperforms pSRAM and Low Power SDR SDRAM in both operation and standby modes, offering significant power savings for mobile and IoT applications.

What applications are suitable for HYPERRAM™?

HYPERRAM™ is tailored for applications that demand low power consumption and robust MCU computing power across various markets, including automotive, industrial 4.0, smart home, and wearables. Examples include dashboards, HMI industrial control panels, smart home devices, voice control devices, bike computers, and smart bands.

In the IoT edge device realm, HYPERRAM™ aligns with design considerations such as low cost, low power consumption, and high computing efficiency.

For battery-powered devices like smart speakers and smart meters, where battery life is paramount, HYPERRAM™ offers a compelling solution. When coupled with power-efficient MCUs, HYPERRAM™ contributes to prolonged battery life, making it an ideal choice for IoT applications.

With its impressive throughput and compact form factor, HYPERRAM™ finds application in diverse markets, including automotive, wearables, industrial, IoT, and smart homes.